Quality matters and in most cases, supersedes quantity. Regardless of how many assets you have, 100 or 1 million, it is in your business’s best interest to keep them in optimal condition. Regular maintenance and timely repair save businesses millions of dollars while ensuring optimal equipment functioning.

Inefficient maintenance translates into lost productivity and bears serious operational and financial consequences for businesses. Forbes quotes that 82% of businesses experience at least one instance of unplanned downtime in three years – some experience even more than that. Such a high frequency of downtimes slows down daily business operations tremendously!

Implementing maintenance routines to cater to, or prevent these downtimes is a standard industrial practice. With this comes generating equipment maintenance logs. If done manually, these can take considerable time, but there’s always a fix.

This article explains what a maintenance log is, its types, how to create one, and an overview of how an asset management system helps generate and leverage maintenance logs for your business.

What is an equipment maintenance log?

An equipment maintenance log is a detailed document that marks all the actions that have been taken on an asset over some time. Basically, it keeps track of the maintenance history. Tracking the maintenance of equipment helps improve their reliability and safety.

A maintenance log consists of two major components that help consolidate asset information:

1. General details

This information is useful in identifying and categorizing a piece of equipment. This typically includes:

- Equipment name

- Asset identification number

- Model number

- Manufacturer

- Location

- Custodian

2. Maintenance activities

This list includes all the actions performed on an asset for maintenance and repair. It includes:

- Details of the maintenance actions

- Type of maintenance activity

- Date when the actions were performed

- Details of the technician

3. Parts and consumables used

The details of all the inventory items utilized to conduct the maintenance activity are a part of this list, including:

- Quantity of inventory items used

- Supplier details and costs outlined

4. Observations

Every maintenance log can have a section dedicated to feedback and observations. Feedback of the maintenance personnel is incorporated into this section highlighting any changes or remarks. Some of its components are:

- Technician feedback

- Recommendations for future improvements

- Details of the unresolved issues

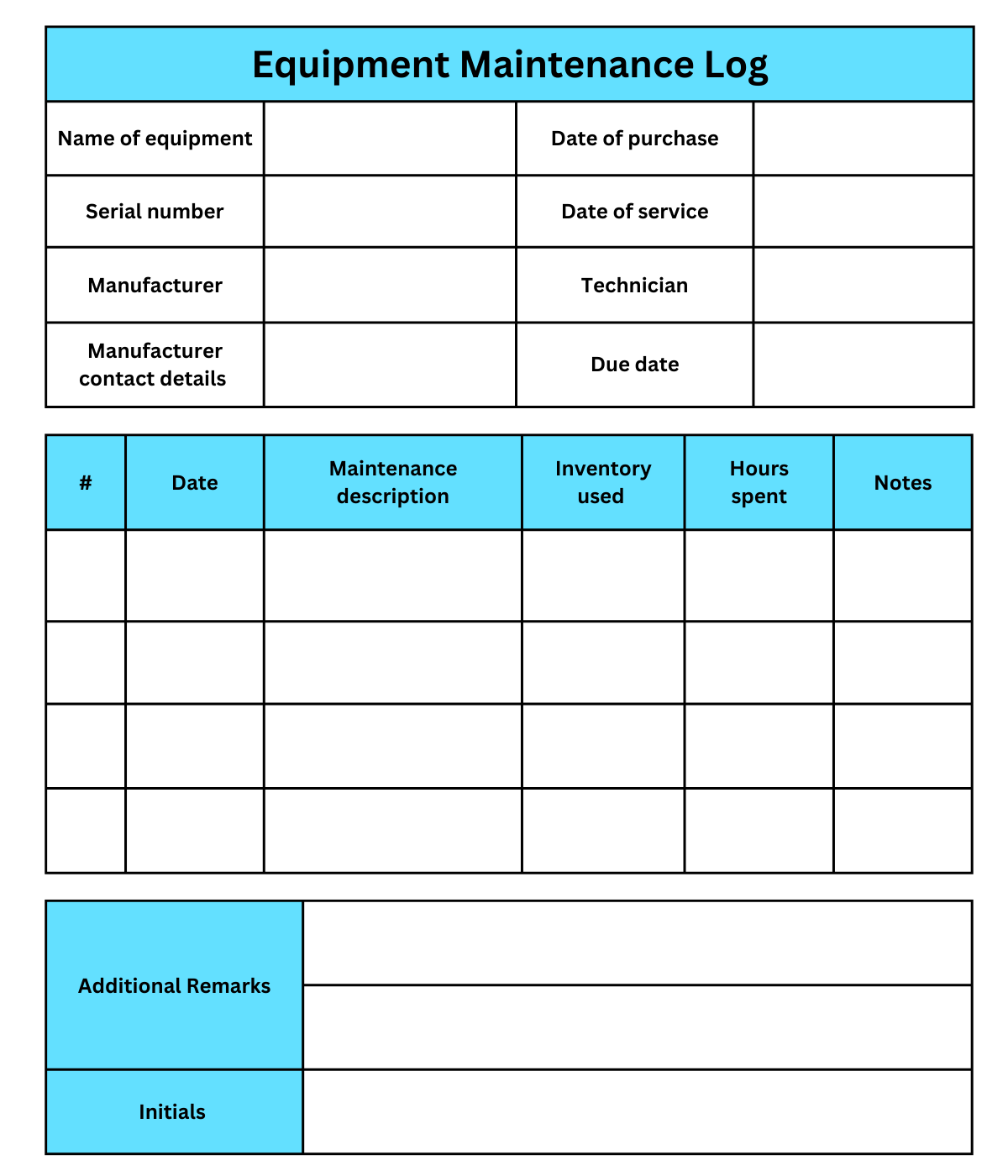

Example of equipment maintenance log

Traditional methods of maintaining logs are time-consuming and they often make data recording difficult and records almost inaccessible, especially in emergencies. These records can get burnt, lost, or even stolen – putting critical data at a serious risk.

An asset management system automates the process of recording maintenance activities, safeguards data, and streamlines the process of equipment log management. Here’s an example of an equipment maintenance log you can upload along with every maintenance request:

Types of equipment maintenance logs

Maintenance logs are a useful way for organizations to keep the equipment running in optimal condition. This enables them to record maintenance history at every step. These records can be for ongoing projects or any assets that require special care.

Service log

A detailed log of all the services performed on an asset, including the asset’s expected delivery date. This way technicians and managers have a holistic view of the past services.

Project log

Multiple assets that have been serviced during a project can be included in these logs. The total inventory consumed on the service can also be mentioned. Only project-specific assets will be a part of these logs so you can accurately assess the final cost of a project.

Maintenance schedule log

Any maintenance activity scheduled for the future is recorded in this type of log. This includes the details of maintenance, the start date of service, and the date of delivery.

These maintenance logs serve as a backbone for maintenance operations. They ensure that the revenue-generating operations are constantly progressing as required without any disruptions due to unexpected downtime. By building on these logs, businesses can increase equipment uptime considerably overcoming operational hurdles.

Steps to creating a maintenance log

A maintenance record performs the function of a maintenance log. You can generate different types of maintenance records pertaining to the needs of your business. However, without a maintenance record, it is nearly impossible to ensure that future maintenance will be well-planned or in line with the asset’s performance historically. Detailed maintenance records help develop a greater level of asset control.

There are a few simple steps you can follow to successfully make a detailed maintenance log, including:

1. Categorize maintenance activities

First, you should identify and list the different kinds of maintenance activities that can be conducted. For instance, inspection, repair, preventive, and warranty checks. You can define the purpose of the maintenance activity. Some examples include:

- Preventive maintenance: Initiating the process of equipment check and repair beforehand to prevent breakdowns. For instance, changing the gear kit in a tractor.

- Corrective maintenance: Conducting the repair activity after a piece of equipment malfunctions. So corrective action is taken after the error is identified.

Identifying these categories helps initiate requests accordingly and enables technicians to identify the required action.

2. Create a standard template

Once the categories have been established, you can generate a standardized template for each type of maintenance. These templates can include details, like equipment name, model number, technician, and a section dedicated to entering details regarding the maintenance procedure. These templates provide a detailed history of the maintenance; so there is a comprehensive record to refer to in the future.

Templates are a direct way to provide information to technicians about past repairs, so the upcoming repairs are in line with the asset’s service history.

3. Ensure regular updates

Accurate record-keeping helps prevent errors in repairs and ensures that the technicians are well-updated. You can keep track of maintenance activities and equipmentperformance by regularly updating the maintenance sheet. Determine when an update is needed ; for instance, preventive maintenance checks can be logged in on a bi-weekly or monthly basis.

Moreover, the maintenance supervisor should review the maintenance logs regularly to ensure that the activities are up to the mark. This serves as a quality check and makes it easier for the technicians to get all the information they need from the service record.

4. Get feedback from technicians

Lastly, technicians must review the logs for safety and compliance purposes. They can review the log details so they can cross-check all the steps with the actual maintenance performed. If senior technicians assign the repairs to their staff, they can check the log to see if the correct steps have been followed or not.

Technicians can give detailed feedback on every maintenance task so the implementation process can be improved. Getting feedback from technicians helps prevent delays in maintenance tasks and enhances coordination.

4 reasons you should maintain a maintenance log

Periodic maintenance tracking simplifies the task of dealing with maintenance issues with a maintenance log. It not only maintains a maintenance history but helps maintenance personnel and technicians:

- Minimize the number of expensive repairs

- Identify inventory trends

- Increase operator safety

- Improve equipment health

As per a report, maintenance costs range from 15-40% of the total production costs. Automating the recording process reduces maintenance errors and the inspection time – in turn, the production costs – improving overall repair response time. An asset management system comes equipped with maintenance schedules that help you schedule maintenance and also generate maintenance logs automatically.

Let’s look at some ways maintenance logs improve your asset utilization and increase equipment uptime:

1. Increased asset safety

By creating a historical record of assets, you can document an asset’s condition over time. Keeping a check allows you to identify the patterns of wear and tear and any factors that might be contributing to frequent repairs. Preventing these repairs and conducting timely maintenance, when needed, prolong the lifecycle of an asset. A well-maintained asset would mean improved performance and a reduced need for frequent equipment replacement.

Many accidents take place in industries due to unplanned equipment failures. Timely repairs, routine checks, and scheduled maintenance help ensure that your equipment is safe to operate and error-free.

A major part of it is conducting routine inspections, such as checking friction material, lubricating gears, and conducting periodic scans. The primary purpose is to improve the overall condition of the machines you own and increase the general safety of your business landscape.

Leveraging enhanced asset tracking, you can schedule inspections when required to maintain safety. It also holds the operator accountable for performing required inspections and reduces the chances of accidents or incidents due to faulty machinery.

2. Reduced upfront costs

Detailed maintenance logs are a useful way for businesses to assess when a piece of equipment is likely to be replaced. With clear visibility into the equipment maintenance history, you can track the lifecycle of a piece of equipment at a glance. This includes checking the date of procurement, maintenance checks, inspections, and maintenance intervals.

This helps save your business considerable costs. For instance, if a new generator costs $4000 and it costs $3000 to repair it every year – it will be better to buy a new one for improved efficiency and long-term sustainability.

Simply, the absence of proper maintenance records can lead to frequent unexpected downtimes. These downtimes inevitably result in missing deadlines and halting the production lines.

On top of all that, you even have to pay technicians overtime for such unexpected failures and the extra money for urgent delivery of parts. By maintaining an equipment maintenance log, you can easily avoid all these issues and save money.

3. Improved resale of assets

Regular equipment maintenance helps keep the assets in running condition. Hoarding assets that are no longer needed for your business due to technological change or obsolescence is of no use. It’s wise to replace them with newer and better versions of the same asset.

One critical factor that determines the resale value of an asset is how well it has been taken care of by the previous owner. Maintenance records help showcase that! They help determine how well an asset has been used and maintained – and whether it can be used by a second owner. Moreover, well-documented maintenance increases the worth of the used equipment as compared to other used equipment that has no maintenance records.

To maximize resale value, a complete and consistent record of everything, including repair schedules, usage logs, and maintenance records, is critical. Such records help boost the buyer’s confidence in the seller’s assets.

4. Reduced risk of data loss

Automated log generation not only helps maintain an equipment maintenance log book, but helps prevent the risk of errors in data generation and recording. With manual record-keeping systems, there is a high chance of data misplacement or theft. It is also difficult to track these records from time to time and use the same maintenance register to record all maintenance activities.

Using modern-day systems you can automatically keep a trail of all maintenance records without missing any step. The date of each maintenance record is documented so there is no discrepancy. Automated records in the system remain safe unless deleted by a personnel, and have designated fields for different types of fields, such as maintenance type, assignee, date of maintenance, and associated purchase orders.

Ways maintenance logs help organize future maintenance

Maintenance logs increase overall equipment safety by providing a historical reference to an asset’s service. Here’s how it supports future maintenance:

Faster repairs and error diagnosis

Detailed records can be provided to the new technicians who have not performed maintenance on an asset yet. These records provide them with a holistic view of an asset’s history, so the upcoming maintenance can be better streamlined.

For instance, a tractor may require only a particular brand and type of gear – the record will state if any repairs have been performed on the gear in the past. This information is highly crucial for early diagnosis of an issue and ensuring faster response to repair requests.

Quick analysis

Analyzing what assets need to be replaced comes from assessing the asset condition and how well it has been performing in the past. This analysis can be based on feedback and numbers obtained from a maintenance log.

Notes on the technical analysis of an asset can be attached to the maintenance log – enabling you to better understand the factors determining an asset’s performance. For example, some features of equipment might require more maintenance than others, so special attention can be given to those features.

Optimized maintenance strategy

Regardless of how many maintenance attempts you make, strategically managing those attempts is the way to achieve efficiency. A well-kept maintenance log highlights how well an asset has been working and if not then identifying the root cause. It helps you recognize if it’s time to change your maintenance strategy in case the existing one does not yield significant results.

For instance, are you using a reactive maintenance strategy, while preventive maintenance is needed? Equipment maintenance logs help provide direction to improve the strategy and implement a better one.

Maintenance logs for optimized equipment maintenance

Optimal equipment performance calls for well-kept maintenance logs. These logs serve as a reference for future maintenance activities and guide the maintenance managers to avoid any challenges in maintenance. All the service costs are recorded enabling you to quickly assess how much a service task is likely to cost – helping in quicker decision-making.

An asset management system provides a holistic platform for users to record, maintain, and track equipment service, including costs and technician feedback. Equipment maintenance logs might be difficult to fill manually, but with automated recording, they can give you deep insights into your maintenance actions. So make your life easier today by leveraging digital maintenance logs!

Frequently Asked Questions (FAQs)

1. What is asset and equipment maintenance?

Equipment maintenance is any activity designed to improve the functioning of an asset and bring it to good working condition. Several methods can be used for equipment maintenance, including, preventive, conditional, predictive, and reactive maintenance.

Maintenance management systems are typically used to conduct and record equipment maintenance from a single platform.

2. What is an equipment maintenance logbook?

An equipment maintenance logbook is a detailed repository of maintenance records highlighting maintenance actions performed on an asset. It provides a reference to an asset’s history, and ongoing and upcoming maintenance routines so the technicians have a bird’s eye view of an asset’s condition.

3. What is a viable maintenance process?

Every organization has a custom maintenance process suited to their needs. However, some common steps define the maintenance process, including:

- Identifying maintenance objectives

- Inspecting the equipment for errors

- Assessing and implementing the right maintenance strategy

- Conducting the maintenance activity

- Tracking the maintenance results

- Getting feedback from maintenance managers and technicians

You can extend the lifecycle of an asset by implementing quality maintenance operations through these easy steps.