- Features

- Integrations

- Pricing

- Solutions

BY APPLICATION

MenuBY INDUSTRY

Menu - Tutorials

- Resources

- Products

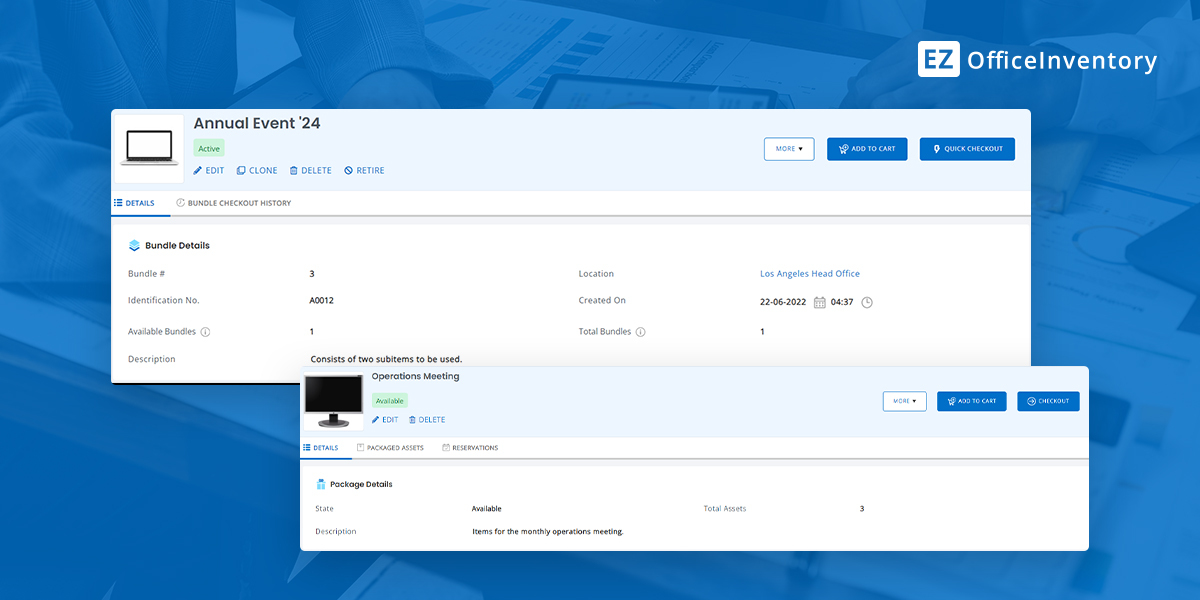

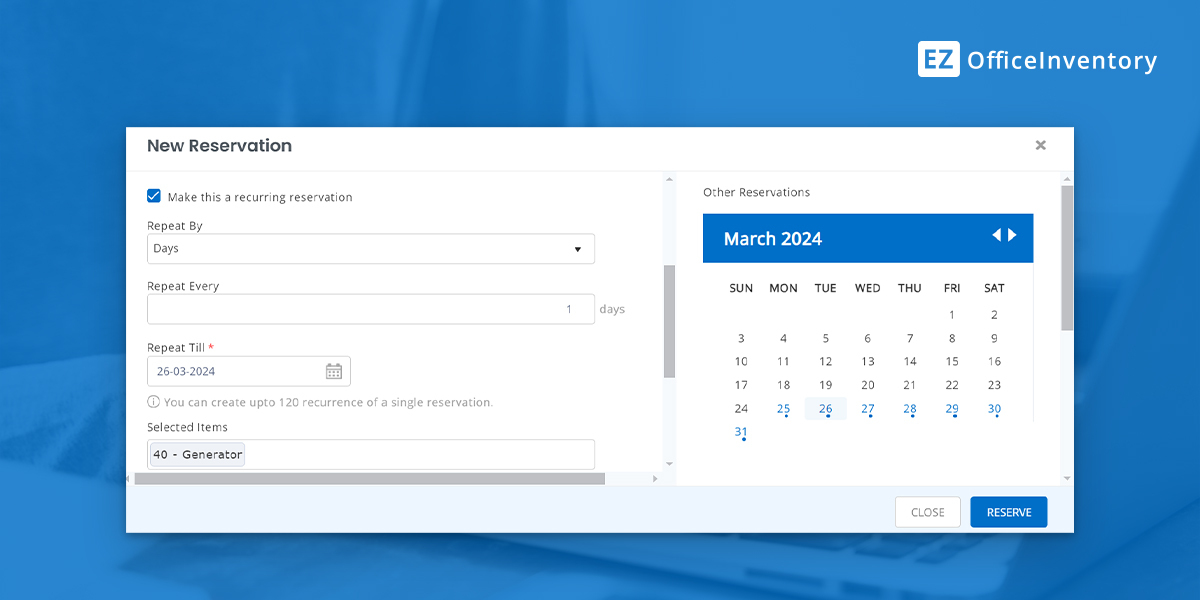

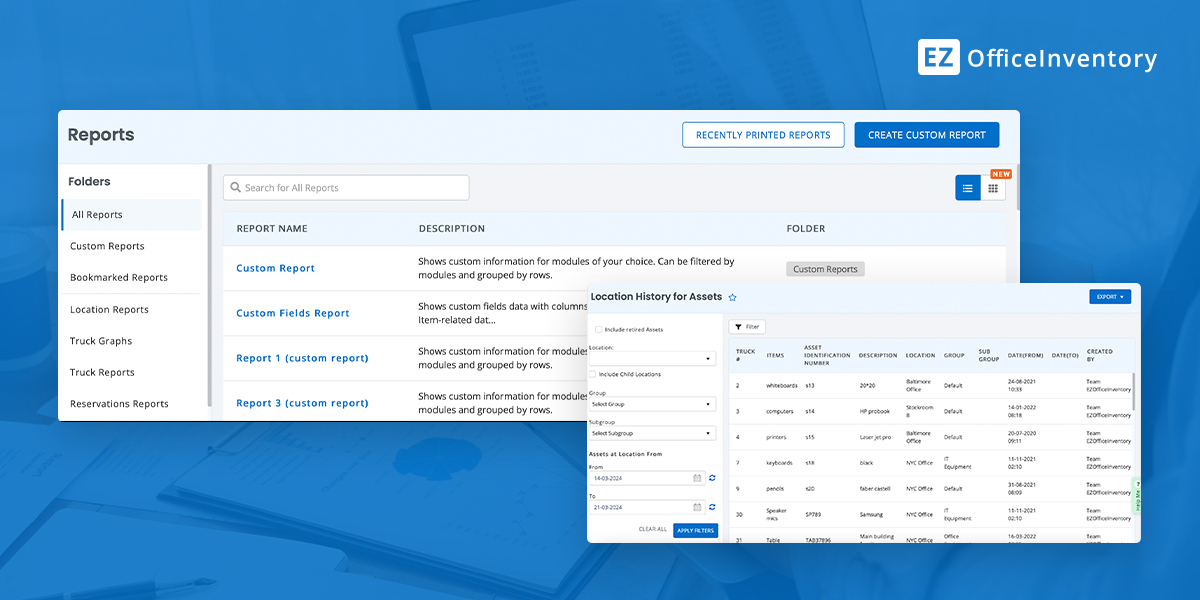

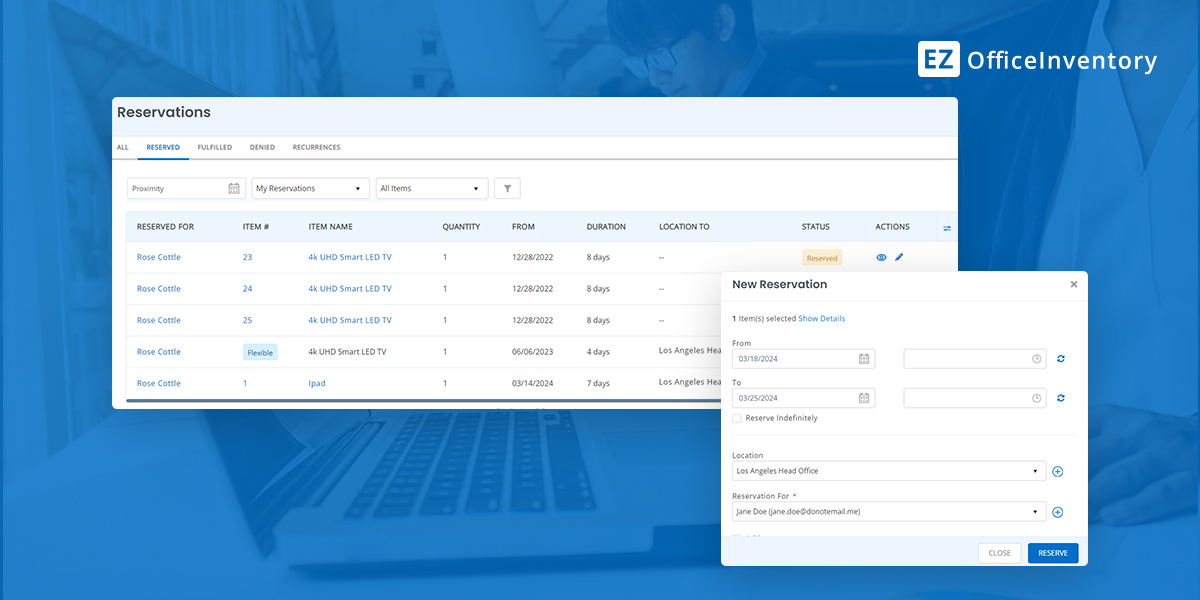

Physical asset management software for total visibility and efficiency

Automated IT asset management for hardware and software

Maintenance operations management solution for equipment and facilities

Equipment rental software to manage your business

- Resources

- Support

- Company

- Contact Us

- Features

- Integrations

- Pricing

- Solutions

BY APPLICATION

MenuBY INDUSTRY

Menu - Tutorials

- Resources

EZO offers innovative asset intelligence and management solutions, trusted by thousands of organizations worldwide.

Products

Copyright © EZO. All rights reserved.