You don’t want a vital piece of equipment to malfunction in the middle of an important task. For this very reason, companies often devise regular service sessions from the very beginning. This helps firms cut down on overhead costs related to extensive equipment replacement.

Practically, these sessions can include oil changes, adjustments, repairs, and even complete overhauls.

Depending on the frequency of use and depreciation rate, most organizations opt for a standardized maintenance schedule. The most commonly adopted schedules are inspired by regulations that American National Standards Institute (ANSI) lay down.

Such schedules lead to preventive maintenance routines. In turn, these routines help companies attain the following objectives:

- Prolonging the life of equipment for greater ROI

- Reducing downtime and delays in workflows

- Lowering risk of error in work tasks

- Increasing safety and protection for employees

What is preventive maintenance?

You might have heard people talking about two kinds of maintenance: predictive and preventive. The former works on the actual usage of the equipment to estimate when it should be sent for maintenance.

For example, you might need to service a vehicle after every thousand miles in predictive maintenance. However, on a preventive maintenance schedule, you will have to service the same vehicle every 3 months.

Predictive maintenance often revolves around the use of advanced technology. Examples of such technology include infrared thermal imaging, or vibration analysis to forecast the cause of equipment failure. As a result of this technology, predictive maintenance has high short-term costs.

Preventive maintenance, on the other hand, can reduce downtimes and improve equipment longevity simply because it is so regular. This is why a lot of industries seem to prefer preventive maintenance to help them improve productivity outcomes.

Which industries benefit from preventive maintenance?

Companies that deal with a lot of expensive or complex equipment are generally prefer using preventive maintenance. These are also the same companies who invest a lot in CMMS, maintenance personnel, and service equipment.

a) The manufacturing industry

One example is the manufacturing industry. A faulty machine or a broken down belt can hugely affect your bottom line in this sector. This is exactly why efficient maintenance management is highly crucial in order to achieve necessary levels of performance.

To use preventive maintenance, manufacturing companies first gather downtime costs. Then they calculate the dollar value of maintenance. Doing so allows manufacturing firms to analyze the true cost of maintenance. After that, they pore over different operational variables which could improve technician response time and optimize long-term workflows.

b) The construction industry

Similar to the manufacturing sector, maintenance is also hugely important for the construction industry. It lets construction firms organize everyday tasks that depend on processes such as belt replacements and oil changes.

Read More: Key Challenges In The Construction Industry

After obtaining the correct guidelines from manufacturers, contractors can create detailed plans regarding how to go about maintenance. Moreover, they can even break down expenditure on the basis of item category, location, status, and more. Heavy equipment maintenance software can help with all of this.

This entire process is especially important in the construction industry because construction equipment is extremely expensive. In fact, the global construction equipment market was valued at 192 billion dollars in 2017.

Source: Statista

c) The food industry

Working in time sensitive work environments also magnifies the need for a preventive maintenance program. This applies to a majority of food processors.

According to a Business Intelligence study, around 97% of the food industry uses preventive maintenance checklist strategies. These are often based on the information contained within their equipment maintenance log. The data these logs provide helps firms keep tabs on expiration dates and usage tracking. They can also help to generate user-friendly reports based on the maintenance activities carried out.

What makes for a great preventive maintenance checklist?

Before you consider finalizing your preventive maintenance checklist, carefully decide which maintenance and inspection activities you’d want to prioritize. A robust equipment servicing program should entail the following:

1) Well organized

A good preventive maintenance checklist must be methodical and intelligently structured. The first step towards this is to ensure you know the following:

- What all your assets are?

- Where are they located?

- What is their status at any given time?

One way to do this is to tag all equipment. You can use Barcodes or QR Codes for this, to store serial numbers, model specifications and other information. All this data makes is easier to schedule and plan inspection sessions for the longevity of your equipment.

2) Process oriented

The best way to conduct successful maintenance practices is to find out exactly what each tool needs. You must define appropriate strategies for each category. And everyone should strictly follow through this strategy every time.

For example, you could define that all company vehicles have to be inspected biannually. This way, you’re less likely to neglect the different kinds of needs associated with different equipment.

3) Time bound

Although maintenance is a long-term process, your preventive maintenance checklists must define the timeframe within which a certain activity must take place. Saying that an air filter must be replaced is no good without laying down how often it needs to be done. So there we go, the secret to a dependable maintenance strategy – repetition and consistency!

4) Regular updates

You should maintain and regularly update special records of all your tools and equipment. Keeping such useful information lets you tweak your service sessions to account for any requisite changes.

For example, you can alter a checklist to include additional maintenance sessions for tools that are being checked out more often than before.

5) Purposeful

A rule of thumb for success in any operational endeavor is to know what you’re hoping to achieve at the end of it. Maintenance checklists are no different.

Say you want a machine to have a 98% uptime in the first 5 years of purchase. After those 5 years, you understand that the uptime will fall slightly. The best move, in this case, is to record the desirable outcome. Then design a maintenance program around it.

Functional areas that need preventive maintenance checklists

1) Interiors

Every workplace comprises of specific types of interiors to facilitate its employees. Depending on the preference of the staff and nature of the work, the administration department allocates a budget for furniture, fixtures and carpeting.

Due to the daily use of such items, they are subject to frequent wear and tear. Therefore, it is suggested to regularly inspect them for loose parts and broken switches with the help of a preventive maintenance checklist. All office appliances also fall under this category and need supervision to perform optimally.

2) Exteriors

If you recently faced a heavy rainfall season, then you must already realize how critical it is to manage exteriors. Direct contact with harsh weather conditions make the repair and servicing of grounds, drains and dumpsters quite challenging. Luckily, a maintenance checklist lets you organize a schedule to keep exteriors looking perfect, all the time.

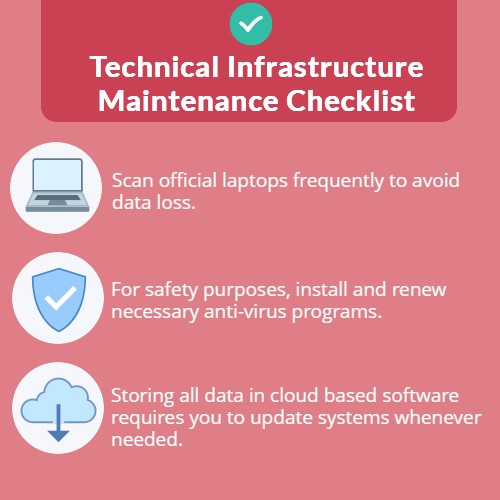

3) Technical infrastructure

With the rise in demand for technical infrastructure, the ratio of IT assets to employees in various sectors has increased considerably. This means that consequently, the average business invests more in electronic devices now than it did in the previous years.

Source: Applied Computer Research, Inc.

Such a trend signifies the need for high level data security through timely maintenance. Hardware and software both need frequent check-ups to avoid unwarranted data loss and tampering.

4) Heating, ventilation, and air conditioning (HVAC)

For the entire life of your office building, you need to keep your HVAC equipment in good condition at all times. This broadly includes plumbing and electricity along with all the heating and cooling appliances as well.

Poor maintenance practices can lead to HVAC equipment breaking down more often. Consequently, these breakdowns disrupt workflows and waste time. Such incidents create disturbances and makes it harder for employees to focus on their daily tasks.

5) Safety

Unforeseen natural disasters and bad practices in health and safety pose a great threat to office buildings. To tackle such situations, it always helps to make the necessary preparations in advance.

To guarantee safety for its staff, every company has fire escapes, security cameras and fire extinguishers in buildings. Since no one uses such equipment regularly, it is common to neglect their maintenance. This, of course, is a bad idea. You should always service and inspect safety tools on time so that they are ready for use in emergencies.

6) Vehicles

Employees sometimes have to travel for meetings and conferences across locations. This is where company vehicles come in. For sectors such as construction, vehicles are a primary asset for off-site projects as well.

Organizations own different types of transportation, from company cars to delivery trucks. Just like every other physical asset, vehicles also need scheduled service sessions. A preventive maintenance checklist helps here. It lets you keep track of oil and tire changes and other mechanical repairs.

Basic checklist templates you can build upon!

The best solution to take care of all your office equipment is to prepare a preventive maintenance checklist. Here are a few things to include on various functional checklists to improve the efficiency of your work operations:

1. Interior Maintenance Checklist

- Conduct a timely examination of the flooring, walls and ceiling and furniture to spot any degeneration.

- For pipes and other water resources, check if there are any leaks.

- Do a thorough inspection for any electrical device hazards.

- Make sure the toilets, faucets and showers are in working condition.

- Depending on your usage, test the smoke detectors and fire alarms.

- For electrical devices, keep an eye out for loose wires or fixtures. Call an electrician if necessary.

- If you work within a multi-story building, keep your elevators functional.

- Ensure cleanliness by vacuuming the carpets.

- Empty all garbage containers within the building.

- Check all kitchen equipment, especially stoves and hood filters. Make it a point to clean them. Additionally, get rid of grease and any inflammable waste.

- While using complex wiring structures, ensure that you don’t overload a circuit. Moreover, avoid creating tripping hazards.

- Keep your stairs and railings properly fixed to lower chances of injury.

2. Exterior Maintenance Checklist

- Schedule frequent check-ups of the paint on building walls.

- Ensure all locks and main gates are properly functioning.

- Try to keep the building aesthetically appealing. Consider investing in a care routine for plantation.

- Remove any signs of algae or other dirt from the walls or grounds.

- Due to ill-frequent use, rooftops are often a mess. Therefore, make it a point to inspect them regularly for litter or cracked tiles. Be careful when working on high places. Always use safety precautions.

- Conduct frequent water tests through the roof gutters and drains. Flush water through the downspouts to check their working condition.

- Get rid of water blockages outside the building after heavy rainfall.

- Keep an eye out for any cracks in window frames and glass. If broken, handle with care.

- Sometimes, the door handles get loose. Therefore, service all external hardware regularly.

- If you have a playground, inspect all equipment to ensure no one gets hurt.

- In case of an accident, examine the ground for cracked glass or debris.

- Go over all roof penetrations.

- Inspect all trees in your vicinity for chances of falling branches.

- Ensure that the fencing is standing strong. Replace in case it seems flimsy.

3. Technical Infrastructure Maintenance Checklist

- Storing all data in cloud based software requires you to update systems whenever needed.

- To avoid accumulating extra information, clear out your browser files as soon as possible.

- In order to make preparations beforehand, configure your startup programs in advance.

- Scan official laptops frequently to avoid data loss.

- For safety purposes, install and renew necessary anti-virus programs.

- Clean your monitors, keyboards, printers and other equipment to remove any dirt and debris.

- Use a suitable liquid to polish projector and monitor screens.

- Make sure you organize your cables to avoid short-circuits.

- Make it a point to run disk cleanups.

- If your employees have their own hard drives, defragment them for optimal usage.

- To keep all data safe, perform timely system backups.

- After any technical changes, reboot the system to ensure everything is working as before.

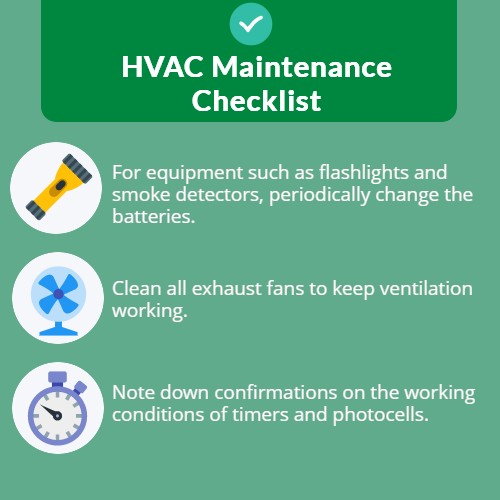

4. HVAC Maintenance Checklist

- For equipment such as flashlights and smoke detectors, make it a habit to change batteries every now and then.

- Note down confirmations on the working conditions of timers and photocells.

- Thoroughly inspect cover plates for any cracks. In addition to this, be sure to maintain proper tightness.

- Clean all exhaust fans to keep ventilation working.

- Regularly replace air filters depending on usage.

- If blower motors are making excessive noise during operations, get an electrician to examine them.

- Fix and secure any loose guards and panels.

- Perform regular tests on safety controls and relevant equipment.

- Monitor compressed air lines frequently. Also, work to spot any leaks in pipes, tubes or fittings.

- Inspect oil levels of air compressor pumps. Remember to replace them when necessary too.

5. Safety and Inspection Maintenance Checklist

- Conduct an inventory check and replenish all your first aid supplies.

- Make sure safety signs are in place.

- Properly label all your equipment.

- Carry out regular inspections on respirators.

- Keep all your fall protection harnesses and kits in good condition.

- Frequently check on security cameras and get them fixed if need be.

- Service fire extinguishers on a timely basis.

- Lubricate all heavy equipment to prevent any accidental breakdowns.

- Properly segregate any areas where access is denied due to safety risks.

6. Vehicle Maintenance Checklist

- Check your cars for fuel levels every other week.

- Use gauges or dipsticks to check fluid levels in the coolant and antifreeze.

- Ensure all safety items, for example brakes, horns and steering, are working properly.

- Schedule regular service sessions for drivability issues such as misfire and rough idle.

- In case of accidents, refer the respective personnel to get the broken glass and windows fixed.

- Keep track of when the heaters and air conditioners of your vehicles require repair.

- Inspect your serpentine belts often. Also, remember to get them changed when necessary.

- Examine the batteries and contacts in case of vehicles heating up.

The need for structure in preventive maintenance

Preventive maintenance is widely adopted by numerous organizations and firms. There are several reasons behind this adoption. For starters, preventive mainteannce lowers overheads and increases equipment longevity. Additionally, it also promotes safety across the board.

It can get quite difficult to manage multiple assets and tools through manual repair sessions. For this reason, companies must draft preventive maintenance checklists. This helps to streamline service events.

With details on vendors and manufacturers available, you can easily get the best advice you need regarding routine inspections and examinations of all your tools. Listing down all maintenance activities also allows you to measure progress and design budgets for replacements when needed. This gives you a chance to derive the maximum possible outcomes while simultaneously raising ROI!